Going, Going, Gone... What Happened to the Pattern Makers?

Seriously, where are the pattern makers?

The pattern making crisis is real. Pattern makers are disappearing.

If your business makes patterns you will be affected.

Already affected? It is not too late to act, there are remedies.

What’s the problem anyway.

Local pattern making skills are vanishing:

Simply put there are fewer pattern makers.

Remaining pattern makers are older - at or nearing retirement age.

Training and apprenticeship programs lag industry demand.

Young workers are choosing other professions.

Bottom line is the shrinking pool of pattern makers has to be addressed. Here are 4 options to consider:

Option 1: Invest in Training for Legacy Manual Pattern Making

This is an obvious solution, but not immediate. It requires full, and ongoing commitment, not half measures. One issue is that you freeze productivity around a legacy pattern making approach. This may result in a weakened position against competitors who pursue more automated solutions.

Bottom line:

Doable? Yes.

Sustainable? Yes.

Competitive advantage? No.

Option 2: Outsource Pattern Making to Low Cost Markets

Many companies have already used this option since it can be significantly cheaper. However sending patterns 8,500 miles over seas also has some significant issues. Design intent, and production time are two of the biggest.

Producing patterns consistent with design intent is tricky enough when stakeholders are close, let alone overseas.

Designs are sent over seas.

About two weeks later, patterns are sent back.

The patterns often don’t fully reflect the original design intent.

They are re-sent and several iterations later the design intent and the produced patterns are consistent. But this takes significant time. Which is the second issue.

8,500 miles back and forth at 2 week intervals can light your time on fire and burn it to the ground. To alleviate this many stakeholders make biweekly, or monthly overseas visits to increase areas of control that lead to faster turn around. Making it work may cost more money despite the initial attractive price.

Bottom line:

Doable? Yes.

Sustainable? Yes.

Competitive advantage? No.

Option 3: Implement Digital Patterning

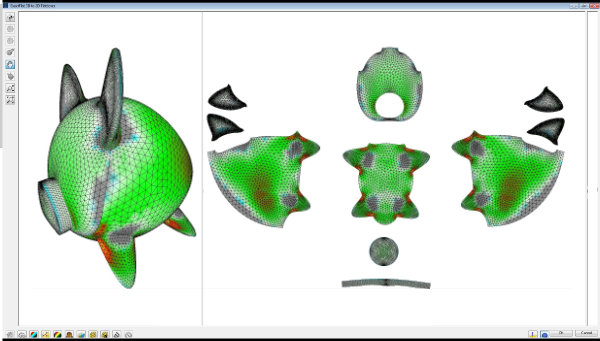

The digital revolution has already delivered remarkable benefits in so many areas. It is now so mainstream, it is taken for granted. In pattern making, the advancements involve using 3D digital designs as direct input into the 2D pattern making process.

Digital patterning technology utilizes fabric simulations which account for shape, and realistic material stretch, as the complex surfaces flatten from 3D designs into 2D patterns. Integrated patten engineering tools simplify the process of adding pattern features such as seams, notches or hardware tags.

Bottom line:

Doable? Yes.

Sustainable? Yes.

Competitive advantage? Absolutely!

Learn More about the Competitive Advantages of Digital Patterning

Of course there’s always the option to "do nothing” and continue with the status quo until the competition over takes your business. But if you’ve read this far it’s a safe bet that you know you need to make some type of change. Of all of the options discussed, the move to digital patterning provides the only practical approach to addressing the loss of traditional pattern makers. To learn more just click on the link below and schedule a time to speak with one of our experts.