Why some Marine Canvas fabricators are more profitable than ever.

Marine Canvas and Seating Manufacturing Requires Patterns

The Marine industry was particularly hard hit during the last economic downturn. There was virtually no boat buying or building in the late 90’s and early 2000’s. Boat builders and repair businesses had to drastically cut costs and shed product lines to survive. Custom canvas fabrication shops were especially impacted by the slow down.

Legacy Manual Pattern Making Processes Drain Profitability

Pattern making, the essence of the Marine Canvas Fabricator's business, is a slow, costly manual process largely unchanged in 50 years. Fabricating awnings, biminis, covers, and interiors often involves hours or days of manual measurements, “drape and tape” rough patterning, test material cutting and sewing, and then editing the patterns until they fit perfectly. This manual pattern making process is highly inaccurate and the time spent preparing, measuring and reworking can be a significant drain on profitability.

The traditional "Tape and drape, then “pattern, cut and fix" process is time consuming, and costly.

Digital Patterning - Automation That Matters

Eclipse Yachts of Palm Beach Florida not only survived the downturn, but they fought back and rebelled against the disadvantages of the traditional pattern making process. To reduce costs and improve production turnaround times, the team at Eclipse decided to focus on changes that eliminated manual efforts and automated repetitive tasks.

Starting with the rallying cry of “Automate Everywhere,” they prioritized updates in several key process areas including:

Part measurement - getting the basic dimensions for the part in 3D CAD

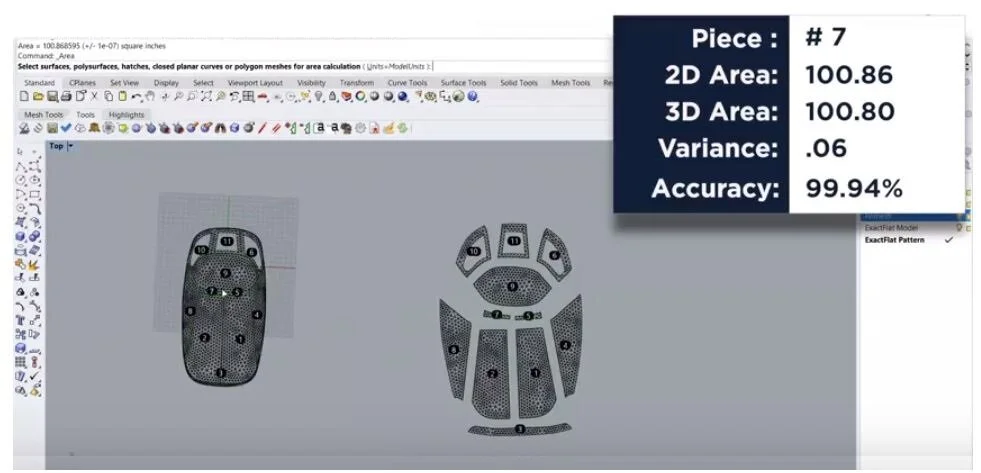

Pattern creation - creating the initial 2D patterns directly from the 3D model

Drawings generation - associating features like seams, notches, and hardware to the appropriate locations in 3D and 2D

Better Patterns, and 50% shorter time to market

Eclipse adopted ExactFlat for SOLIDWORKS digital design patterning solution. The result? “Time to market was reduced by a stunning 40-50%.” According to Joy Hutchinson, Founder and President of Eclipse Yacht Canvas. “...we’ve eliminated the iterative, manual processes that had become the industry standard. We can now respond faster to our customers’ needs, and it’s winning us more business.”

The entire process change was achieved in roughly 5 weeks and cost less than half of what Eclipse typically spent annually on over time for a single pattern maker. To learn more or to start saving time and increasing profits in your marine canvas business give us a call.

About the Author

Mark Jewell has over 25 years experience working with more than a thousand soft goods manufacturers in 15 countries. He specializes in building and implementing software tools to help his clients avoid failure, reduce the risk of change and to make sure that they get the most from their process automation investments. If you want to improve pattern making productivity, then you want to speak with Mark.

Refreshed and Reprinted - From April 2018