Growing Market Share and Profits – Footwear

The Footwear Market is changing – Fast!

“The thing that will most define 2019 will be the speed of disruption and the pace of our consumers — they’re going faster and faster. As retailers, as businesspeople, we have to keep up with them.” – Dick Johnson, President and CEO, Foot Locker

Increasing demand for sports shoes and designer shoes are responsible for the majority of growth in the footwear market (MarketWatch report – Nov 2018). With every passing day the industry becomes more and more competitive. New brands seem to appear overnight. Each offering distinct innovations as well as the promise to provide consumers with the exact shoe or accessory that they specify.

Mass customization or “personalization” of footwear starts with the 3D CAD model. This virtual representation of the shoes enables the designers to validate features, catalogue components (BOM, and to create renderings used for sales and marketing.

Production innovations for personalization are driving success.

Though technology has marked its presence in the modernization of the footwear industry, most of the production is still done by hand. Major fabrication related challenges in the Footwear Industry include:

Inefficient timing and delivery of products resulting in shortages and missed sales

Excessive production and inventory leading to outdated stock

Increased cost of Warehousing and Store logistics which consumes profit

One key to capturing growth in this segment centers around a brand’s ability to quickly react to customer specific requirements. This is particularly true as it relates to footwear style, materials and sizing. While the implementation of 3D CAD (design, virtual samples, etc..) and PLM tools seem to be givens, most of the other business critical automation technologies discussed here are just beginning to find widespread adoption.

Once the design is approved, Digital Patterning software solutions like ExactFlat automate the next step of the process. With these tools the 3D models are converted into 2D pattern pieces in minutes. The direct link between the 3D model and the 2D patterns also means that the inevitable client changes can be transferred to the pattern immediately.

3D Digital Patterning

Produce patterns in minutes

3D digital patterning software solutions close the gap between design and production automation. These tools are used to convert the 3D design models and associated graphics into 2D, production-ready materials. The primary benefits are the speed, most designs are converted in minutes vs. hours or days using manual processes, as well as the accuracy. 2D patterns generated using digital patterning tools are incredibly accurate, eliminating the time and cost associated with fit testing and production re-work.

Digital Textile Printing

Personalize the look

Another unique benefit of the transition to digital comes from the ability to precisely link the graphics to the patterns. Pattern-to-Graphics integration results in tremendous time and test materials savings. It also provides brands with a cost-effective way to deliver a personalized look for every client.

Once linked the graphics are printed “on-demand” using the new generation of textile printers. This equipment produces high-quality output on an ever-increasing selection of materials. The printed fabrics are then ready to be cut using the new generation of vision-enabled cutters like the Z1 Cutter from Gerber Technology.

This integration of design, 3D to 2D flattening, textile printing and automated cutting makes production-on-demand a cost effective reality.

3D Bonding and automated sewing

Manufacture Cheaper, Faster, and Locally

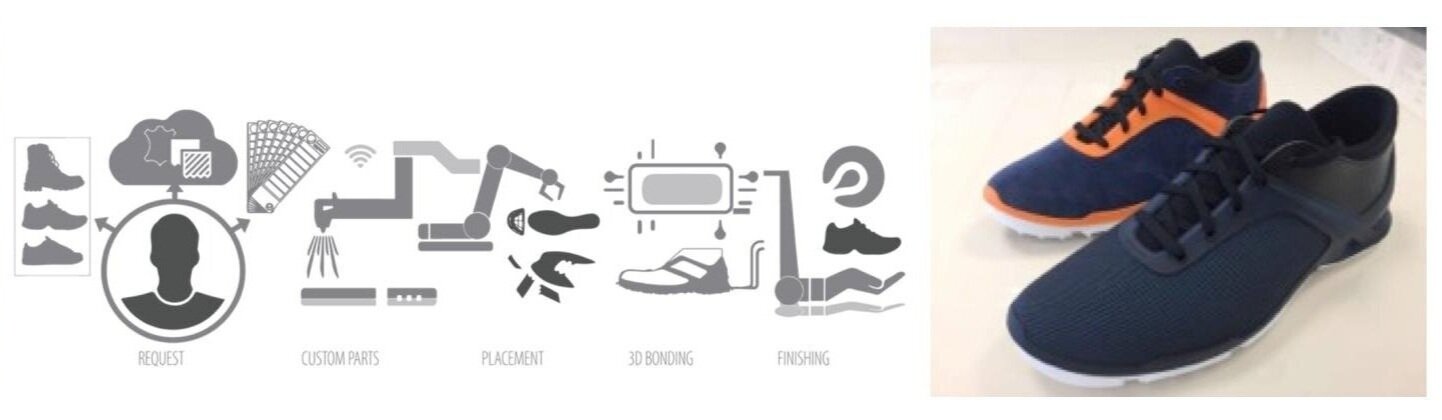

The printed materials integrate seamlessly with automated cutters and piece labeling equipment. 3D Bonding and automated sewing are newer technologies used in the final stage of production. Implementing these solutions enable brands to dramatically reduce labor costs. They are also instrumental in helping manufacturers lessen their reliance on outsourced manufacturing. This in turn helps shave costs from production and manufacturing logistics.

Mastering digital technologies is the key next step

The speed of change in the footwear industry dictates that brands must enhance their processes to remain competitive. Adopting the digital pre-production capabilities described here provide the only practical way to address the “style-on-demand” requirements for shoes.

To learn more, click on the link below and schedule a time with our experts. Let the team at ExactFlat help your company evaluate, select and implement the right technologies for your business.