3D Scanning Automates Retrofit and Redesign

Digital Design, Patterning and Manufacturing technologies are revolutionizing the time-to-market and profitability metrics in textile-related industries such as Furniture, Marine Canvas and Fashion.

Apprehensions surrounding the use of 3D CAD continues to standout as the biggest barrier to the adoption of these business-critical solutions. Particularly when creating after-market pieces such as boat or automotive covers and re-upholstered seating.

One of the technologies helping address this is the latest suite of 3D Scanners. These tools reduce or eliminate the need to:

become experts in every details of 3D CAD products

rely on antiquated tape-and-drape methods to capture the existing product design

The newest generation of lightweight, portable and easy to use scanners can quickly create precise 3D models of real-world objects. These 3D models can then be converted into accurate 2D patterns in minutes using digital patterning solutions like ExactFlat. This combination of technologies helps to lower manufacturing costs and to bring products to market in a fraction of the time it took just a few years ago.

Workflow Benefits

Step 1 – Capture the existing product or prototype quickly

Professional grade scanners from industry leading providers such as Creaform and Artec, offer the best option because of the quality of the initial scan and the speed of model capture. 3D Scanners can be calibrated to capture every detail of the existing product, giving manufactures quick and easy-to-implement access to the benefits of a digital design to manufacturing process.

Step 2 – Generate precise 3D models from the Scan

Scan editing software like DesignX from 3D Systems is used to help convert the scan data into precise 3D surface models. The resulting 3D model can be validated against reference points in the original product, and then subdivided into patches to improve compute performance. Time-savings at this stage can range from hours to days saved and easily justify the price of both the scanner and the editing software.

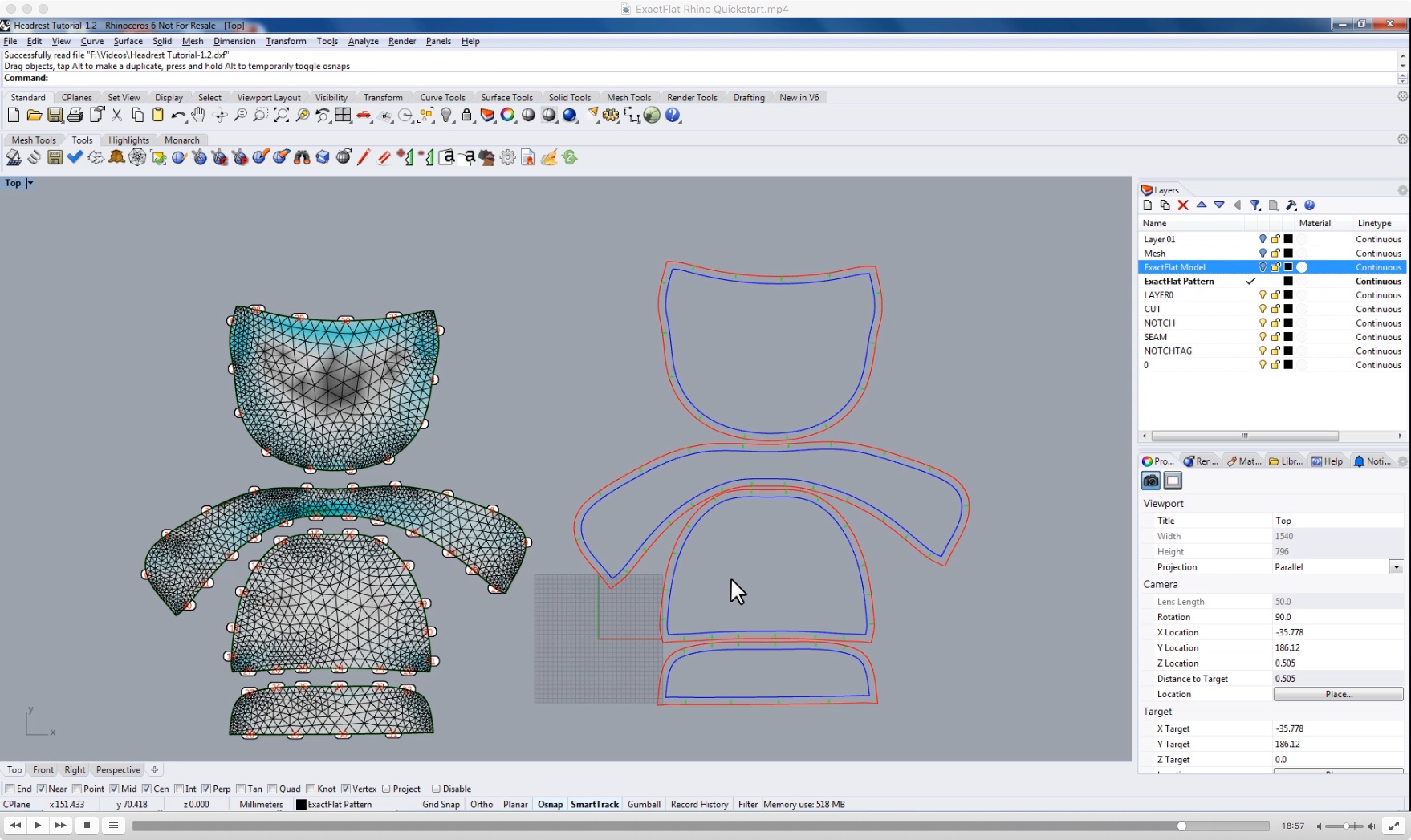

Step 3 – Convert the 3D model into a 2D pattern

Using the entirely digital process, convert scans into 3D surfaces and then to 2D pattern pieces in record time.

ExactFlat is then able to import and make use of the scan data directly in most cases. This change to the pattern making process is another huge cost-saving tool. 2D patterns automatically generated from the edited 3D scan are extremely accurate. As an added benefit, manufacturers can validate pattern fit without iterative cut and sew steps. This again helps reduce overall production costs.

Learn More (www.exactflat.com)

3D scanning plays a significant role in productivity improvement. The process benefits apply in any situation where taping and draping of a physical mock-up or mannequin is the typical starting point for the design process. Click here to schedule a meeting.

About the Partner

For over 30 years the team at 3D Systems has bridged the gap between inspiration and innovation by connecting their clients with the expertise and digital manufacturing workflow required to solve their business, design or engineering problems.

Scan to pattern webinar - December 6, 2018

ExactFlat is partnering with 3D systems to host a series of webinars. These events showcase ways to utilize digital scanning, design and patterning to improve productivity in any industry. Click on the images to learn more.