Using AutoDesk Fusion 360 and ExactFlat to Fashion a "Super" Suit for Comic-con

In this article, we’ll explore a digital workflow to design and fabricate a custom-fit superhero suit for Comic-Con the largest (and most discriminating) assembly of pop-culture fans in the world. The designer Hung Nguyen (lover of 60's comics) from SolidCAD Canada and his son used the Autodesk Product Design and Manufacturing Collection and integrated apps from ExactFlat and Pepakura to get the job done.

What’s the problem anyway?

- Traditional machine design experts find it difficult to impossible to take advantage of their current skills and tools when they need to design, validate performance and then produce products for textiles or fashion clients.

- While the 3D design capture and creation tools are starting to address the requirements of these users a new generation of flattening and digital patterning tools are also needed to get the job done quickly and cost effectively.

- Worse yet, presenting a badly designed and/or constructed costume at Comic-Con can be devastating to a young person’s ego.

Getting the design right – quickly.

With very little time (and not a lot of money to spare) Hung started the process with ReCap Pro and converted human scan data to a 3D mesh model. Next, he refined the 3D model with ReMake and then used Fusion 360 to prepare the model for production.

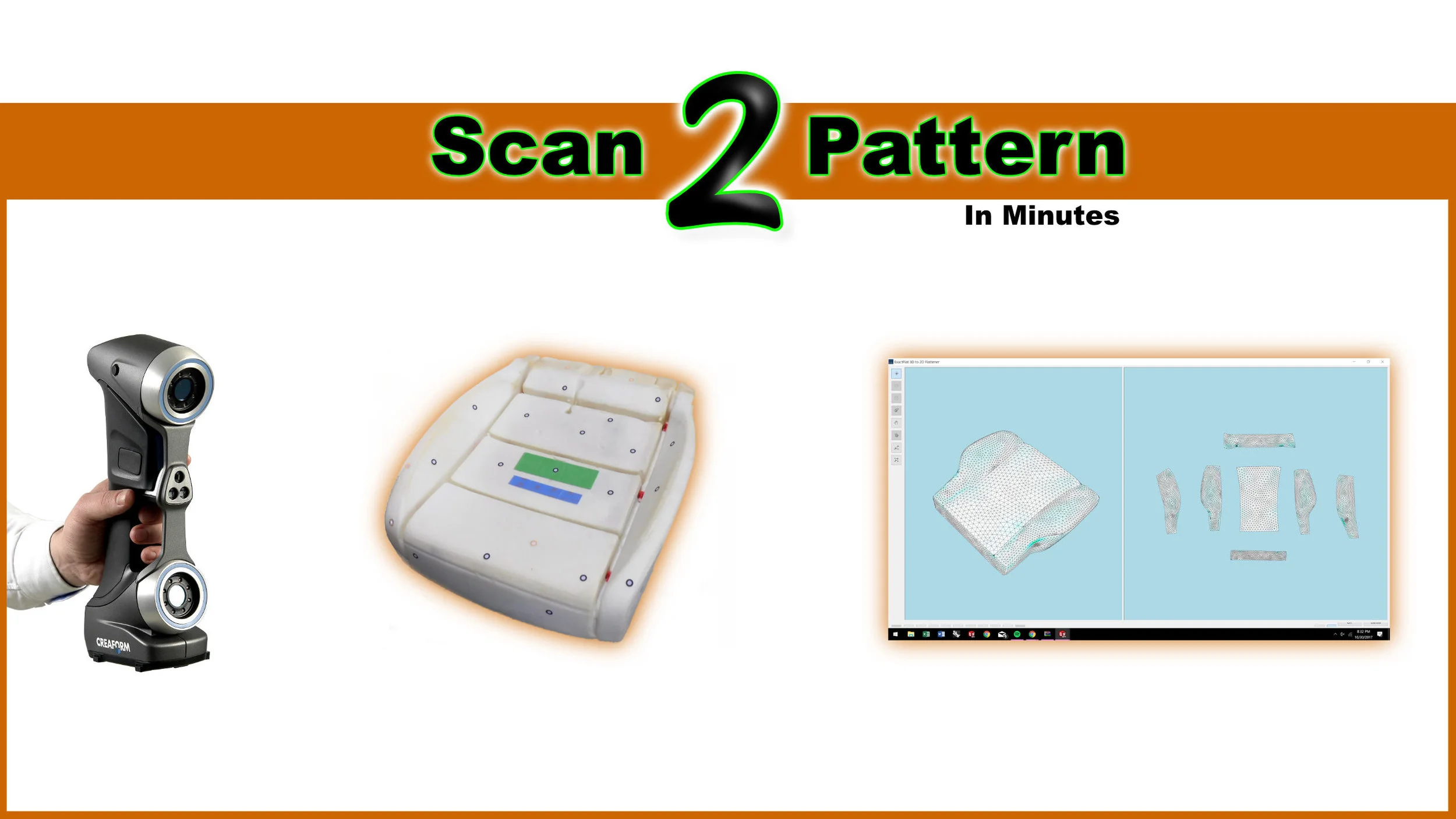

After that he moved to the pre-production stage and created perfect flat patterns in just a few minutes with ExactFlat Online software.

Once he has the patterns right Hung used nesting software to optimize the material cost and then generated CNC code using Fusion 360 CAM 2D profile cutting. The last step was to assemble all the parts together, and the custom-fit Ironman suit was finalized with perfect shape and size for his son.

Digital Patterning – Bridging the gap between design and production.

ExactFlat flattening made it easy for Hung and his son to realize their vision for this innovative project. The digital patterning steps are:

- Design your product in 3D

- Prepare the 3D model for flattening

- Flatten the 3D model into 2D patterns

- Optimize the pattern to reduce strain and sag

- Finish the pattern engineering process

Piece creation and pattern optimization are the two critical steps.

Piece Creation

3D models typically consist of groups of “faces.” The challenge is that faces may not align with the “pieces” that need to be cut. So, there is a piece creation step needed to “Prepare” the design for flattening.

In this example the team used the ExactFlat Publisher Plugin for Fusion 360 to combine faces into pieces. To start they selected the “Create Pieces” tool, then named the pieces. After that it’s a simple process to click on the appropriate faces to add to the piece and to repeat the process until all of the desired pieces are defined.

2D Pattern Optimization

The other key part of the process is optimizing the pattern for strain and sag. This is done with a combination of digital patterning features and helps eliminate the “guess work” and iterations associated with manual patterning processes.

First use the Pre-Flatten tools in ExactFlat to generate the rough pattern. The Pre-flatten tools are purpose-built to ensure the best pattern piece based on surface type from nearly flat, to complex curvature to wavy. This enables flattening of nearly any shape.

Once the rough pattern pieces are generated, the optimization step is done. Optimization provides a view of the pattern shape as well as highlighting areas of strain or sag in the pattern. Knowing this before anything is cut is critical for saving time and materials.

ExactFlat utilizes a database of various textiles and their engineering properties plus an internally developed FEA solver to simulate how those fabrics behave under load. These industry-proven algorithms enable users to optimize 2D patterns to ensure that the finished 3D textile covering will not only fit properly but bear up under stress.

Once pattern pieces have been optimized, ExactFlat allows users to add features and PMI data, such as seam off-sets, alignment notches, or piece tags for hardware placement (i.e. buttons, zippers, etc.)

The final step involves exporting the pattern for use in other production tools such as nesting, the process of tightly packing the various 2D shapes to minimize material waste, or cutting on CNC or laser cutting tables.

Here is a video of how the final project turned out:

Summary

- Digital Patterning can play a major role in the design and fabrication of any type of textile where the product is created from or covered in fabric. With fabric, unlike sheet metal, distortion happens in both the x and y axis and it’s very difficult to predict the final 3D form from the 2D cut pieces.

- ExactFlat’s solver starts with the 3D form and then simulates the material distortion and displays areas of strain and sag. Calculations like this are extremely difficult but, through theoretical and applied work, ExactFlat’s solver delivers the high degree of confidence that customers need.

- New tools, no matter how powerful, must fix within the user's current environment and skill set. ExactFlat is a simple to use 3D to 2D flattening solution created to enable textiles manufacturers to gain the full advantage of the transition to a digital design, patterning and fabrication process.

To learn more or to see the process in action join us at Autodesk University 2017 and attend the live session titled: