The Apparel Microfactory: A New Item On The Menu.

The transformation to digital continues at an accelerated pace. A consequence of this in the fashion and garment markets is the Apparel Microfactory. Just like microfactories that have come before, it will set the stage for new dynamics and new winners and losers.

What is the situation?

- 3D digital design, digital patterning, and digital print technologies are primed for mainstream adoption in apparel markets.

- The primary reason for adopting digital technologies is changing. It will soon be: I need to do this to survive (we call this the AutoCAD moment.)

- The faster, lower cost and smaller footprint digital workflow will enable a new player in the ecosystem: The Apparel Microfactory.

- High quality, affordable goods use to be enough. Now customers are placing premium value customized offerings that reflect personal tastes and expression. We all want to belong to a group, but paradoxically, we also want to be unique and different.

The Microfactory Paradigm

Large factories are seen as more profitable and more efficient. But that is no longer the case with digital technologies. Small factories, a fraction of the footprint, can be just as profitable. Also, they offer a significant advantage in that it is a fast, nimble, environment where ideas can evolve into real products. This “Concept-to-Creation” advantage is particularly critical in apparel markets. Why? Apparel markets are unique in the speed and turn-over of product. This is because they must account for:

Seasonal variation

Geographic variation

Consumer taste variation

Retailer preference variation etc.

The Essential Element of the Apparel Micro Factory: The Ability to Get It Just Right, Right Now.

This is the unspoken and unapologetic mantra of the consumer. Those who meet this demand will thrive. Advanced manufacturing tools, workflow for rapid prototyping and a small scale (unit of 1) and the ability to scale up production to produce a meaningful number of units are just costs of entry.

The old paradigm, with the customer affinity around companies and brands, is shown on the left. This will continue to be a marketplace reality, but it will not be the only model. The apparel microfactory, with its smaller, faster operating model will introduce another paradigm into the mainstream.

While custom clothing or made-to-measure items have been around for some time, they have been limited and expensive. The Apparel Microfactory will give customers wider range of options at a cheaper price.

It Is Not Theory, The Microfactory is Already A Reality

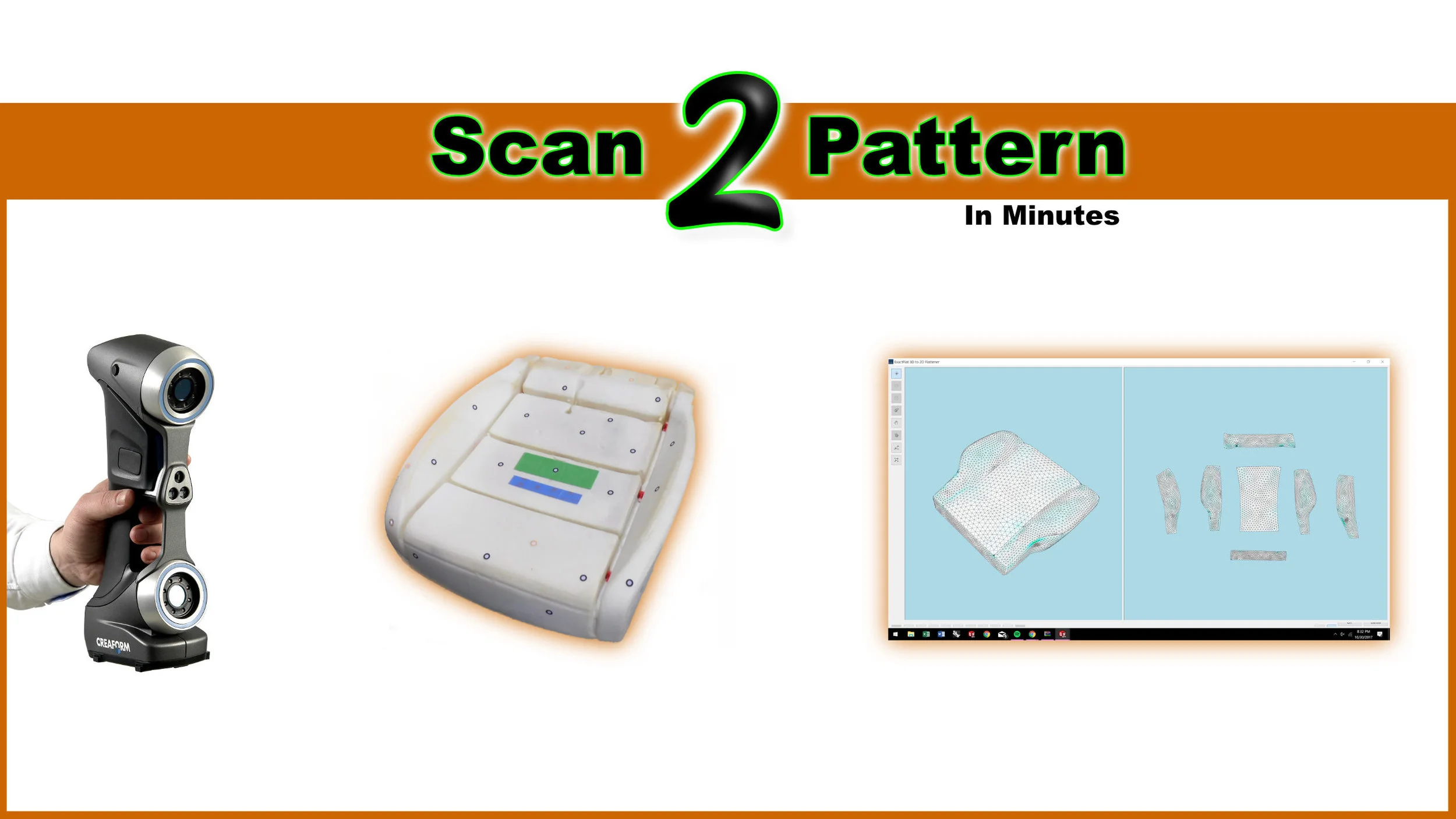

The Apparel Microfactory is based on three core tool sets.

- 3D CAD

- Digital patterning

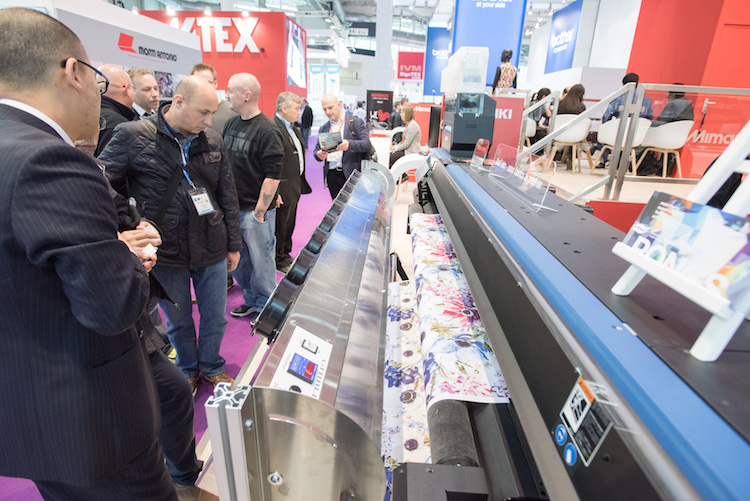

- Dye Sublimation Printing & cutting tools

As it stands now, the three core toolsets are being better and better integrated. We see the integration continuing to evolve in ways that have already been successful. For example, 3D CAD tools are well integrated into many industry workflows. There are 3D CAD tools for Plastics, Sheet Metals, Electrical, Milling etc. This template will apply to apparel markets as well. Manual pattern making is already being replaced at an accelerating pace and giving way to digital patterning. 3D CAD and Digital Patterning offerings are available and provide dramatic improvements in workflow speed.

Bold Prediction

Connection to the customer will rule. Right now the formidable new mega player in the mix is the collective impact of the "micro-influencer."

- Anyone with a significant Instagram following will be able to create a fashion brand.

- Skateboarders, mountain bikers, surfers and any other niche sport athlete can have their own fashion brand, not just Tony Hawk or Rob Dyrdek.

- Popular Youtubers will be able to create a fashion brand.

It is just a matter of time and they are coming for their own piece of the pie. They have a supreme advantage in the connection to the customer.

Summary.

- The Apparel Microfactory gives designers and producers powerful "concept-to-creation" capabilities.

- This will help win customers with offerings that reflect personal tastes and expression.

- Companies that do this successfully will win a spot in the customer's orbit. Those who don't will be invisible.

- Apparel Microfactories are real. They are based on 3 key tool sets: 3D CAD, Digital Patterning, and Dye Sublimation Printing.

What are your thoughts? If you want to talk shop, we'ed love to here from you. Click here to schedule a call.