Digital Patterning is here. Are you ready?

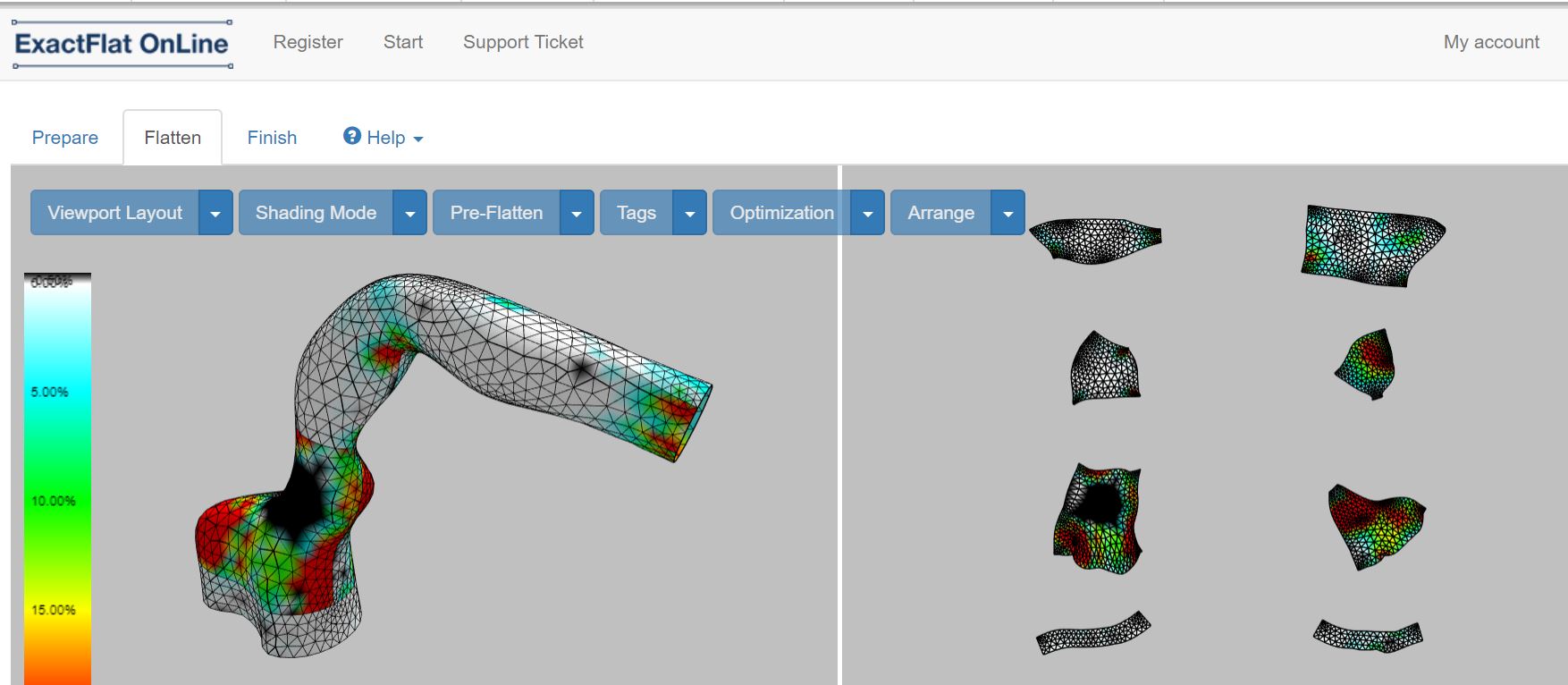

The adoption of digital technologies in the soft goods (products made from or covered in fabrics) industry is no longer "the road ahead." The use of 3D design, digital patterning and production automation software is now part of the mainstream method for this segment.

Is your business prepared to leverage these tools to gain or maintain competitive leadership?

Take the Digital Readiness Challenge

Take a few minutes and analyze your business' digital readiness quotient (DRQ). Just review each of the 10 questions and add up the Points.

Process

1. How do your pattern makers capture the design?

Create a Sketch (1 Point)

Scan a Physical Prototype (2 Points)

Build a 3D CAD model (3 Points)

Re-use the 3D model created by your design team (4 Points)

2. How do you convert the design into a pattern?

Use the “Drape and Tape” process (1 Point)

Digitize a prototype (2 Points)

Flatten a 3D CAD file with a sheet metal flattening application (3 Points)

Use digital patterning software to simulate the exact performance of the fabric (4 Points)

3. How do you add production data (seam tables, notches, BOM, etc...) to the pattern?

None is needed (1 Point)

With AutoCAD or Adobe Illustrator (2 Points)

Manually in a legacy pattern design software product (3 Points)

Automatically with associative data in an integrated design and patterning solution (4 Points)

4. How do you optimize material usage?

We do not optimize material (1 Point)

We optimize material usage manually (2 Points)

We use automated nesting software to optimize material (4 Points)

5. How do you ensure fit?

Build a paper model, then prototypes using the desired fabric and then iterate (1 Point)

Start with a series of fit models using a test material or the desired fabric and iterate (2 Points)

Analyze the fit in the software then create a single fit test model (4 Points)

Business Goals

6. How long does the pattern making process take today?

A day or more ( 1 Point)

Less than half a day (2 Points)

Less than an hour (3 Points)

20 minutes or less (4 points)

7. If your process was twice as fast what would you do with the extra time?

Increase the number of projects per month (4 Points)

Focus our resources on other activity (4 Points)

Golf, read a book or find some other way to improve work-life balance (4 Points)

8. How many patterns do you create each month?

Less than 5 (1 Point)

5 to 30 (2 Points)

More than 30 (4 Points)

9. How often do you get a perfect fit on the first try?

Always (4 Points)

Sometimes (2 Points)

Never (0 Points)

10. What is the biggest bottleneck in your process?

Creating a pattern (4 Points)

Determining material usage (4 Points)

Getting a perfect fit (4 Points)

Assembling or installing the product (4 Points)

What's your DRQ?

Add up your points from each of the questions. If you scored anything less than 40 points then your business may be missing out on the productivity advantages of 3D design and digital patterning. Why not meet with the experts at ExactFlat to see how they can help. Just click on the image below to schedule a one-on-one session.

ExactFlat - The Leaders in Digital Patterning and Soft Goods Production Automation.