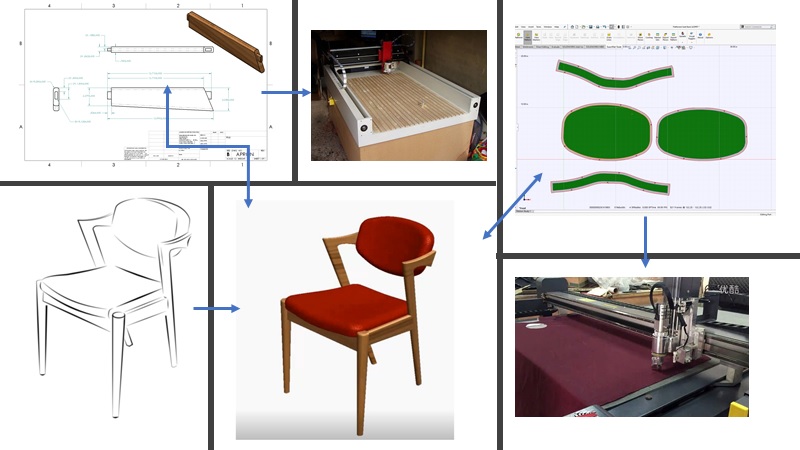

3D Combines Frame and Fabric for Faster Furniture Design

Integrating the Entire Design of the Piece

The design of “hard” furniture components (ex. the frame of a chair) has benefited greatly from the widespread adoption of 3D CAD. However, the process for defining the soft components (ex. foam and fabric) is done separately from the rest of the design. To make matters worse this disjointed soft goods process typically requires time-consuming steps including:

creating physical prototypes,

then “draping and taping” to generate rough patterns,

and then on to digitizing patterns and iterating on the final design.

Integrated 3D CAD with Digital Patterning solutions like ExactFlat for SOLIDWORKS provide a reliable way to eliminate these steps and to produce flat patterns and fabric production materials in conjunction with the hard components.

Managing Change

In addition to the fabric design process time reduction advantages, the integrated hard goods/soft goods approach also addresses the issues associated with design change.

Customers typically iterate on the design and fabrication details because of issues with:

design: the design isn't quite right just yet

communication: specific details of the design were either not shared or misunderstood

fit: the patterns don't fit properly

production: changes are needed to address production constraints or costs or schedule

With a disjointed process, changes required for either the hard or soft components must be identified, tracked, re-created and then checked repeatedly until the product is manufactured. The integrated digital design process eliminates the time wasted in this approach by associating all parts of the design into a single digital model.

Realize the Benefits of Integrated Design Today

Manufacturers looking for a competitive advantage can reduce manufacturing time and production costs, as well as improve design flexibility by transitioning to an entirely digital process. SOLIDWORKS and ExactFlat for SOLIDWORKS are the proven solutions in 3D Design and 3D-to-2D flattening software. Click on the link below and schedule a time with one of our experts to learn more.

About DASI Solutions

The presentation and demonstrations shown in this example were created by the experts at DASI Solutions. The team at DASI Solutions are dedicated to service and support of manufacturers in a host of industries, especially the furniture design community. Offering SOLIDWORKS engineering software solutions, accompanied by best-in-class training and support, the team is passionate in playing an active role in building partnerships and success stories with their clients.

Digital Design Webinar: Best Practices for Furniture Makers.

To see the solution in action, click on the image and sign up for the next Digital Design: Best Practices webinar hosted by DASI Solutions and featuring ExactFlat.

Dec. 5, 2018. 11:00 am EST. Space limited. Click to Register.