Patterns in Minutes - Automotive Trim Cover Design - Part II

Finishing the Patterning and Pre-Production Processes

Preparing fabric and leather pattern pieces for automotive trim production requires just a few steps:

Design

Patterning

Material and Labor Cost Analysis/Optimization

Manufacturing (Cut, Sew and Assemble)

The legacy manual methods for the Patterning and Cost Analysis/Optimization consume most of the time and cost of in the overall process. These valuable steps can be automated and, in most cases, streamlined and executed in less than half of the time. Digital patterning software solutions like ExactFlat for SOLIDWORKS provide the only practical way to automate and accelerate these business-critical tasks.

In previous articles we'd reviewed the steps to convert 3D designs into 2D flat patterns utilizing digital patterning software. Here, we'll discuss best practices for reducing the time and effort associated with the pattern detailing steps. Details of each step can be viewed and executed using the ExactFlat Quick Start training program found on the website. (https://www.exactflat.com/quickstart).

Add Pattern Design Elements

Once the initial 2D pattern has been generated, the next step of the process is to incorporate all of the details into the cut file (marker sets) and assembly drawings. Using ExactFlat, pattern detail and marker standards information for your company is stored in a shared database. Seams, materials, hardware, costing models and manufacturing process requirements are all organized such that this information can be applied directly in the drawing environment.

The integrated database method allows standards information to be shared or customized across your entire organization and supplier network. This ensures consistency which minimizes production errors and costs. The database is pre-loaded with ready-to-use industry standard information. All of the data can be edited and expanded to meet your specific company requirements.

Seam Allowance, Notches and Hardware features are all added with just a few clicks. Associations between the 3D model and the 2D pattern pieces ensure that pattern details added in either environment automatically appear on the corresponding piece.

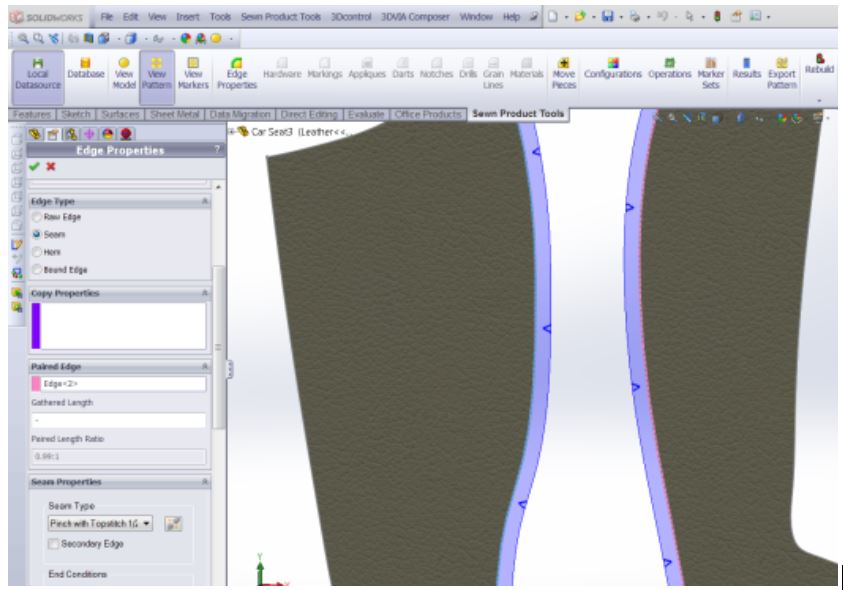

Seams

Seam Allowance or "salvage" is added by first simply selecting the pre-defined seam type from your company approved standard list and then clicking on the edge where the seam will be applied. Seam types can be applied globally (i.e. to all edges with one click ) or individually depending on your production needs.

Notches

ExactFlat provides access to a wide variety of notch types and styles. Notch arrays and parametric notch positioning are also supported. Pattern piece edges retain information about the neighboring edge from the 3D model. This means that when a notch feature is added to one pattern edge, then a matching notch is automatically added in the same location on the adjacent pattern piece.

Hardware

Hardware (buttons, zippers, snaps, etc...) are specified using 3D models, blocks, or lines and points and then transferred and accurately positioned in the 2D flat pattern. The database in ExactFlat is used to store the hardware items and can be searched at any time in order to find the right component.

Try it now

In Part III, the next and final article in this series we'll explore the advantages of digital pattering on cost analysis and production drawing generation.

To learn more about how your business can utilize digital patterning and production tools to improve your trim design and production process click on the link below. You'll be able to schedule a time to meet with one of our experts to discuss the best solution for your needs.