Does Your Pattern Making Leak Profit?

The biggest lie about processes that "work" is that they can also leak time and profit.

Profit leaks can hide in plain sight.

Manual pattern making workflows are no exception.

To find and fix leaks, consider updating your process with digital patterning.

What’s the problem here?

The purpose of a business is to find and then satisfy the needs of a customer at a profit.

To do this businesses undertake various actions to create value.

From the customer perspective, "value" is any action or process they are willing to pay for.

If you undertake actions, the customer is unwilling to pay for, you are leaking potential profit.

Start by checking your manual pattern making processes for the following

1.) Profit Leak Vampires: Conversion, Recreation, Translation, and Adaptation

In legacy manual pattern making, first you convert a digital design to a physical prototype. The physical prototype is used to create physical patterns. Then you recreate those physical patterns into digital versions. Next you take the digital version of the patterns and translate to a different file format to create documentation. Lastly you adapt the total work in progress to a format for creating cost estimates. Conversion, recreation, translation, and adaptation of work in progress leaks profit everyday. To reclaim your profit and plug the leak, completely eliminate the need to convert, create, recreate, or translate any process.

2.) Time Bandits: Waiting in the Queue

Time bandits occur when time is elapsing but no work is progressing. This typically happens at work-in-progress hand-offs. For example: you finished your patterns, now they have to be sent to the team that does the nesting. It gets put in the queue and when the nesting team is able, they start to process the nest order. Or, for example, when sending finished patterns to get documentation and assembly instructions. Again the work goes in the queue, and waits until it can be taken on.

Legacy manual patterning processes are particularly problematic since there is rarely process, or tool compatibility between different steps of the workflow For those interested in increased productivity, go looking for the “queues”. That is where you’ll find the profit leaking time bandits.

3.) Process Inflammation Symptoms: Low value repetitive tasks.

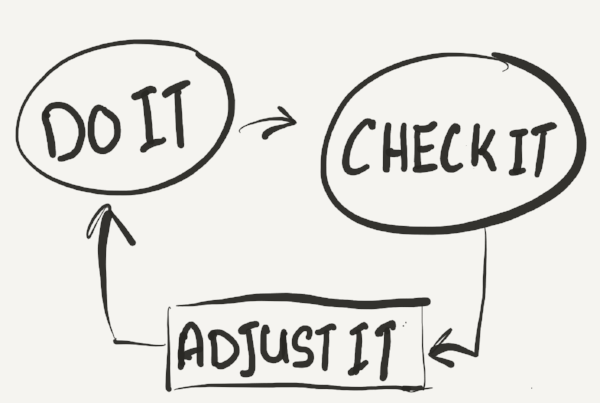

You do the work, but it is not quite right the first time. You do it again and iterate several times more until you do get it right. This is a fact of life for environments with manual pattern making. Now what happens when there is an upstream design change. It causes this inflammatory response due to the cycle of repeat iterations at every step of the process. If the inflammation is very painful, it usually gets addressed immediately. If it is lower level chronic inflammation that leaks the most profit because it becomes chronic.

Digital Patterning: Faster and More Profitable

If your looking at ways to combat time and profit challenges, then it may be time to consider the transition to digital patterning. Digital Pattering software solution like ExactFlat close the automation gap by linking design and production into one, integrated solution. Manufacturers world-wide have implemented ExactFlat because it is:

A silver bullet for the profit leak vampires,

A Texas Ranger for the time bandits, and

An easy to follow, healthy diet, for process inflammation.

Want to learn more about how you can put these tools to work optimizing your business? Click on the image below and schedule some time with our experts.