Dye Sublimation Printers - 3D Printing for the Fashion Industry?

3D printing or additive manufacturing is transforming the short-run production process for industrial products. This technology allows manufacturers to meet exacting customer requirements by producing built-to-order solutions at the same cost or economy of scale that was previously only achievable via mass production. (see “The Coming Revolution in Additive Manufacturing” Dassault Systemes, 2013).

Dye Sublimation printers have the potential to have a similar or even greater impact on custom production in the fashion and apparel industry. These tools coupled with digital design and patterning software allow designers to create or change design concepts in a matter of minutes and then to cost-effectively produce the desired garments virtually on-demand.

What's the problem?

To remain competitive fashion designers, large or small, require the ability to:

- produce custom and just-in-time products,

- avoid the inherent start up costs that previously made “run-of-one” fabrication impractical.

In fact the ability to profitably delivery a short run of products has now become a requirement for everyone from mom-and-pop shops to fortune 500 companies. A simple Google scan will produce hundreds of companies offering “custom clothing options” with “competitive pricing and industry leading turnaround times...”

Today many of these offers rely on simple variations (i.e. “Your Message/Logo here” or “pick from one of our list of fashion-forward color schemes” In contrast , Dye Sublimation (Dye Sub) printers give manufacturers the ability to take customization to the next level.

Dye Sublimation Enables a Build Quantity of “One.”

For our regular readers we’ve already described the workflow associated with the 3D Pattern to Printing process. A brief recap of the process can be seen here:

What’s important to understand is how this process both enables unlimited customization options as well as eliminates time and material waste. With Dye Sub printers, designers can react immediately to customer customer requests in the same way the industry product manufacturers do using 3D printers.

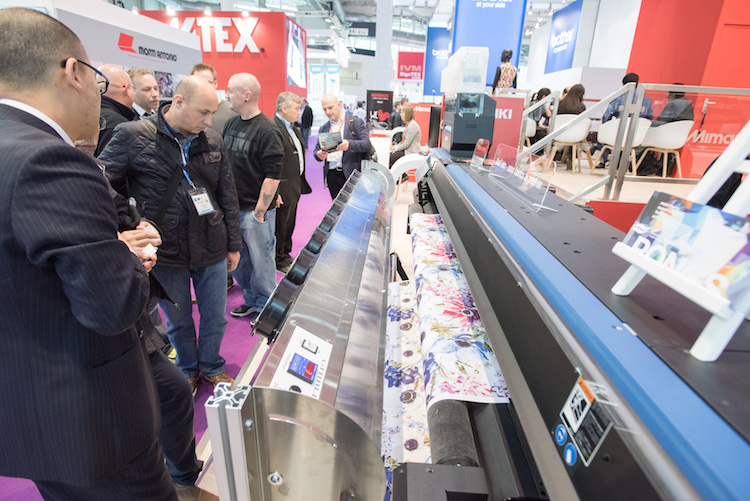

For example, today most custom sport shirt or jacket makers require small; but still mandatory minimum production orders of a design. This is because of setup and material costs for typical transfer or screen printing machines. But Dye Sub printers like those provided by Mimaki http://www.mimakiusa.com/products/dye-sublimation/ts300p-1800/ can print a unique, one-of-a-kind, design on a customer specified material for roughly the same print costs. No setup is required and no excess material is used.

Print your design, one at a time at roughly the same costs with Dye Sub printers.

History repeats itself

Adoption of 3D printers by industrial product manufacturers grew by more than 50% in each of the last 3 years. A Forbes survey attributed the growth to key factors most of which we’ve already discussed in this article. The most prominent being the acceleration of product development.

The majority of these business and fabrication priorities are identical to those currently being considered and debated by fashion designers and manufacturers.

The evolution of the use of 3D printing is roughly covered by a 30 year time line.

It is relatively safe to propose that a similar process evolution and technology adoption cycle will occur regarding the use of 3D Pattern to Print process and that we are in the “broad adoption” stage of the curve. Even a conservative projection allows us to predict a dramatic increase in the use of Dye Sub printers in the fashion industry in the next 3 - 5 years.

- Invented in the 1950’s

- Became practical tools in the late 1990’s

- Experienced dramatic innovations in print speed, ink and textile types in the past decade

- Used for roughly 384 Million Square meters of digital printing in 2015 -2016

- Broadly available by 2020

Summary

The process advantages of digital model can no longer be ignored. Take the production of a custom sports jersey for example:

As you can see from this simple example, The advantages for adopting a 3D pattern to print process can be significant.

What's next

Consumer demand for custom or “personalized” offerings has become the rule in every industry. Digital technologies now allow any company to capture the design, produce patterns and other pre -production materials and then print garments or other items in roughly the same time and at similar costs to legacy printing methods.

Manufacturers in the fashion and apparel industry can begin to experiment with these new tools and to offer the benefits of the "transition to digital" today.

If you want to know more about the 3D "Print 2 Pattern" digital process for fashion and apparel, click the link below and book time to talk to an expert.