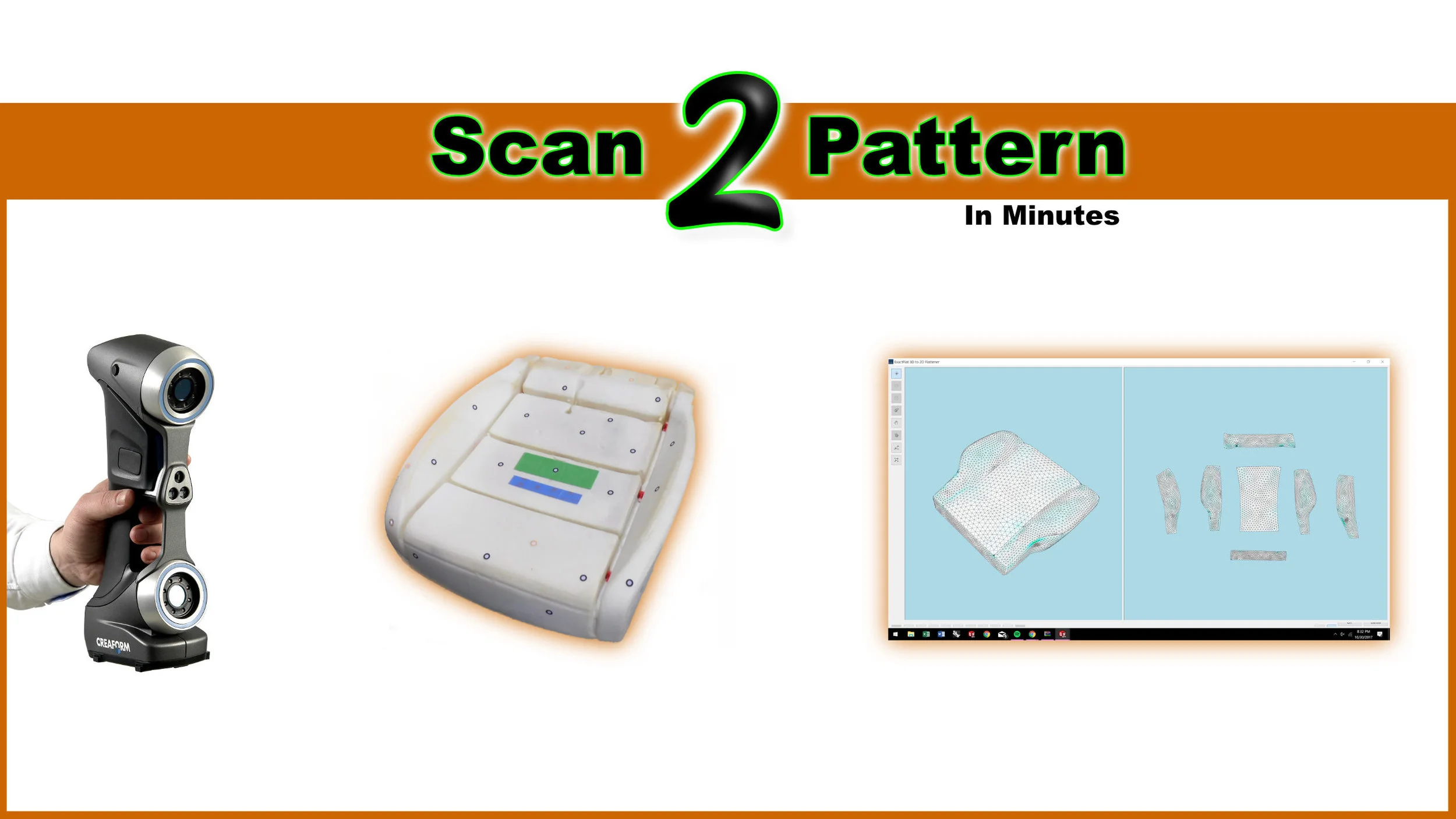

Laser Scan to 2D Pattern in Minutes

The transformation to digital product development in textile industries continues at an accelerating pace.

- The ecosystem of tools continues to advance

- The tools are becoming easier to use

- The tools are becoming better integrated.

The justification for continued use of historical manual processes is at best misguided. The industry is going digital and it is a one way transformation.

Consider the Case of Textiles over Foam.

For industries such as furniture, automotive and transportation seating, interiors for marine, insulating systems for oil, gas, piping, and machinery etc. manual measurement and legacy hand patterning once dominated the way textiles were developed and engineered to fit over top of foam.

It was not uncommon for it to take weeks to complete a single patterning project. Many many iterations, executed by highly skilled pattern makers got the job done. So what happened?

- Pattern makers started disappearing. They got old and retired, much faster than new ones were trained. Now there is a crisis for many since the skills are gone.

- Digital tools matured, got better, faster, lower in price and easier to use. An every year this continues

- Business requirements changed. Fast flexible operation used to be nice to have. Now they are essential for survival.

An Example Of The New Digital WorkFlow.

- Use a 3D Laser Scanner (15-20 Minutes)

- 3D Cad (10-15 minites)

- Digital patterning (10 minutes)

Create patterns ready for sewing in about 35 minutes. Check out the example video to see for yourself (2 min 43 secs)

If you have not already, start your transformation to digital today, call us and talk to an expert