Streamlining Production by Transitioning to 3D Design and Patterning

Furniture makers worldwide are facing increasing profitability and competitiveness challenges. Most of this is due to a few key factors and buying trends including:

A reduced willingness to invest in “heirloom” type furniture.

Consumers want premium quality, stylish pieces but no longer expect to keep the furniture for generations. This means that the appetite for high upfront expense is waning.

A rapidly growing demand for personalized items.

As we’ve noted many times, gone are the days when manufacturers could produce a single style for thousands of clients. It now seems that everyone wants something special, which is made just for them.

What’s the real business problem?

The detailed steps surrounding furniture design are often referred to as tedious, highly iterative, and extremely time consuming. Most of the steps rely on a legacy 2D drawing medium as the primary means of design and process communication. The use of 3D Design, and Digital Patterning solutions replace these methods. This provides manufacturers with access to a simple, cost-effective way to streamline the entire process and ensure overall profitability.

The initial process starts with a conversation where the design team and client select representative furniture pieces that are used as the inspiration for the new project. Previously all of the steps, and communication from that point on were done using 2D drawings. This lead to delays, mis-communications and errors.

How is 3D Design and Digital Patterning helping?

In a recent example, 3D Design and Digital Patterning technologies were used to help a custom furniture maker to compress the design and production preparation process from 4 weeks into just 2 days. While consulting with the team, the process enhancement project focused on their goals and desired benefits such as:

Reducing the time spent from ideation of custom furniture to the final production

Eliminating errors, and time and money waste due to problems associated with missing information or mis-communications

Legacy Custom Furniture Making Process Reviewed

Once the goals were clearly understood, the next part of the consultation involved analyzing their current process to identify opportunities for improvement. It currently takes between four to six weeks to go from an initial session with the client to the proposal and approval meeting, then to iterate on the design and costing and then finally on to begin the manufacturing process. The process also involved at least four design and manufacturing professionals.

Starting with initial consultation with the client, the designers compiles a group of inspiration images to help gain alignment on the design.

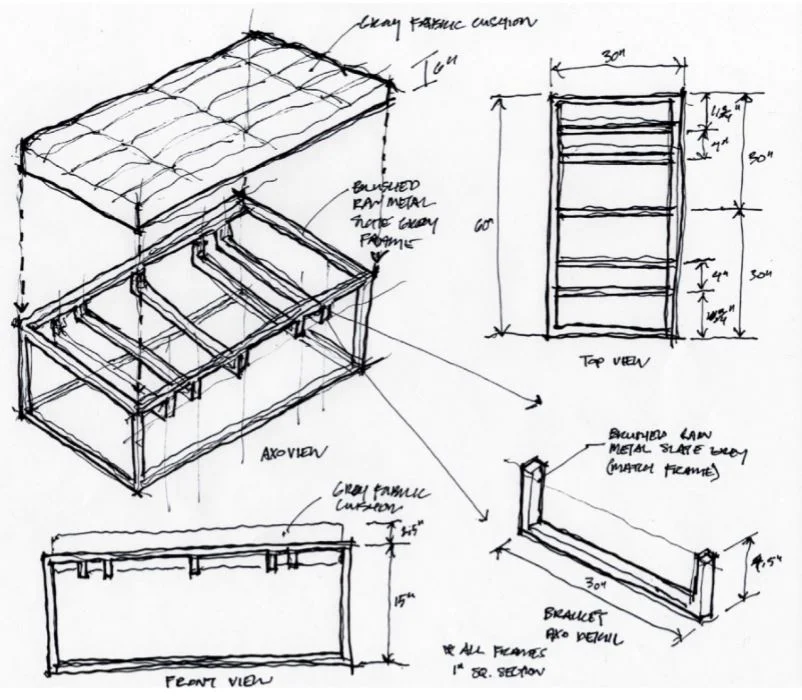

From there, cartoon drawings are made and given to an industrial designer to create initial sketches.

After that an artist makes renderings which are used to review the project with the client.

The inspiration images, sketches and renderings are given to the furniture maker who creates manufacturing documents and edits the concept for production constraints and quoting.

The “tech pack” is then shared with the client and changes are made based on any errors that are found and/or their requests.

At that point, most of the materials are re-created and much of the process starts all over again.

With the Enhanced 3D process, the concept sketch is converted directly into a 3D digital model with all of the dimensions and materials specification needed for production.

At each step in the process a 2D drawing or image is used, reviewed and then re-created entirely from scratch before the next step begins. These repetitive translating and recreating steps delay progress, especially when critical information such as correct measurements, material specifications or desired manufacturing process data is not clear or communicated in sufficient detail. As a result of the review process the manufacturer validated that most of the steps could be streamlined through the use of 3D CAD and 3D Patterning software.

Enhanced 3D Digital Process

Digital software solutions were used to stream line the overall process into just three steps.

Step 1: Inspiration.

Meet with the client to define the project and develop the inspiration materials, reference images and concept sketches.

Precise manufacturing drawings were generated automatically from the 3D model. Eliminating quoting and production errors

Step 2: Design/Approval.

Create a 3D model and renderings from the concept sketches which allow the designer to include correct measurements, and material notes. The 3D model output can be rendered and shared with the client. Adjustments to the design are made quickly in 3D and approval can happen in real-time.

Step 3: Production

Use the finalized 3D digital model to create engineering drawings and renderings from the 3D CAD program of your choice. The design can then go through ExactFlat to create a digital pattern of the soft good material in a matter of minutes. This gives the designer all of the production materials to send to the manufacturer.

2D Patterns were created directly from the 3D model in minutes. Reducing fit testing and avoiding the need for samples and wasted materials.

By transitioning to the digital process, using 3D CAD and Digital Patterning from ExactFlat, the project was streamlined to 2 days involving only 2 industry professionals. Just another proof that 3D and digital provide the only practical way to streamline the process, save time and improve profitability.

Learn More

Learn more about how you can leverage the power of 3D to address your furniture design and profitability challenges. Just click on the image below to set up a one-on-one consultation.

About the Author - Emma Boyle

Born and raised in San Francisco California, Emma recently received a Bachelor's Degree in Industrial Design at the University of Washington in Seattle. Her passion lies with designing products; creating an ease of interaction between people and the objects around them.